Electroplating

Advanced Electroplating Services by Nabtech Engineering

At Nabtech Engineering, we provide top-notch electroplating solutions aimed at boosting the durability, corrosion resistance, and visual appeal of metal components. Our advanced plating methods deliver a protective coating that enhances wear resistance, conductivity, and the overall lifespan of parts used in a variety of industries.

We offer a wide range of electroplating processes, such as Alkaline Zinc (both Rack and Barrel types), Alkaline Zinc Nickel (in Silver and Black finishes), Alkaline Zinc Iron (Rack and Barrel types), CED Coating, Electroless Nickel, and Geomet Coating (Zinc Flakes Process). These coatings provide excellent protection against corrosion, chemicals, and harsh environmental conditions, ensuring your components stay dependable and durable.

For advice or more information call us today at +353 89 253 2612 or email us at sales@nabtechengineering.com

Understanding Electroplating: A Key Metal Finishing Technique

Electroplating is a process used to finish metals by applying an electrical current to deposit a thin layer of metal onto another material’s surface. This method improves the coated component’s resistance to corrosion, durability against wear, conductivity, and overall appearance. The process occurs in an electrolyte solution, where the item being plated serves as the cathode, while the metal to be deposited acts as the anode. As the electric current flows through the solution, metal ions migrate from the anode and adhere to the surface of the object, creating a consistent, protective, and decorative layer. Electroplating is commonly utilized in various industries, including automotive, aerospace, electronics, and industrial manufacturing, providing enhanced performance and longevity for different metal parts.

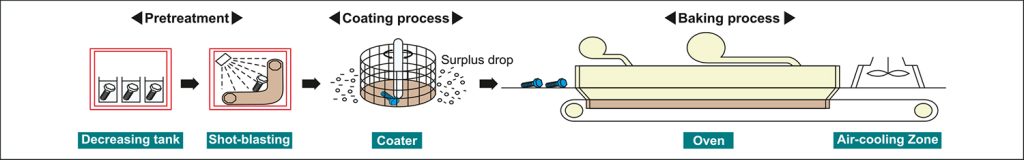

GEOMET PROCESS GLANCE

Electroplating Processes

Each of these electroplating techniques is designed to meet industry-specific requirements, ensuring long-lasting protection, improved mechanical properties, and enhanced aesthetics for a wide range of applications. At Nabtech Engineering, we follow strict quality control procedures to deliver high-performance electroplating solutions that meet global standards.

Alkaline Zinc Processes

Alkaline Zinc Nickel Processes

Alkaline Zinc Iron Process

CED (Cathodic Electro Deposition) Coating

Electroless Nickel Process

Geomet Coating or Zinc Flakes Process

Why Choose Nabtech Engineering ?

At Nabtech Engineering, we provide advanced electroplating solutions with cutting-edge technology, strict quality control, and cost-effective services, ensuring superior protection and durability for your components.

Looking for expert?

Required Electroplating Services? Connect with Nabtech Engineering

Looking for high-quality electroplating services? Contact Nabtech Engineering today for customized solutions, expert coatings, and reliable on-time delivery! For optimal surface preparation, pair electroplating with professional sandblasting.